- Enke ea Flexo UV e bolokehile ebile ea tšepahala, ha e na mesi e ntšang metsi a qhibilihang, ha e chese, ebile ha e silafatse tikoloho. E loketse ho paka le ho hatisa lihlahisoa tse nang le maemo a holimo a bohloeki a kang lijo, lino, koae, joala le meriana.

- Ts'ebetso ea khatiso ha e fetole litšobotsi tsa 'mele, ha e feto-fetohe motsoako, e na le viscosity e tsitsitseng, 'me ha ho bonolo ho khomaretsa poleiti. E ka hatisoa ka viscosity e phahameng, ho khomarela enke ka matla, tlhaloso e phahameng ea matheba, ho pheta-pheta molumo o motle, 'mala o khanyang le o khanyang oa enke, ho khomarela ho tiileng, ho loketse khatiso e ntle ea sehlahisoa.

- Enke e ka omisoa hang-hang, ka bokgoni bo phahameng ba tlhahiso le mefuta e mengata ya tshebediso. E na le kgomarelo e ntle hodima thepa e fapaneng ya ho hatisa jwalo ka pampiri, foil ya aluminium, polasetiki, jj. Sehlahiswa se ka bewa ka hara diphaposi hang ka mora ho hatisa ntle le ho kgomarela.

- Ts'ebetso ea ho phekola le ho omisa mahlaseli a kotsi a UV ke karabelo ea photochemical ea enke ea UV, ke hore, ts'ebetso ea ho fetoha ho tloha sebopehong se otlolohileng ho ea sebopehong sa marang-rang, kahoo e na le litšobotsi tse ngata tse ntle tsa 'mele le lik'hemik'hale tse kang ho hanyetsa solvent, ho hanyetsa ho tsofala le ho hanyetsa botsofali.

- Hobane ha ho na ho feto-fetoha ha di-solvent le dikarolo tse sebetsang hantle haholo, enke ya mokelikeli wa UV e ka fetolwa hore e be filimi ya enke hoo e ka bang 100%, mme tekanyo ya yona e ka tlase ho halofo ya enke ya metsi kapa enke ya solvent, mme e ka fokotsa haholo dinako tsa ho hlwekisa di-plate tsa kgatiso le di-roller tsa anilox, kahoo ditjeo tse felletseng di tlase haholo.

- Enke tsa UV li ka phekoloa feela tlas'a khanya ea UV, kahoo li ke ke tsa oma ntle le khanya ea UV mochineng o hatisitsoeng, e leng se lumellang enke ho bolokoa bosiu bohle selibeng sa enke ha mochine o hatisoa bosiu bohle.

Ha ho kopanngoa litšobotsi tse boletsoeng ka holimo, enke ea khatiso ea UV flexo e na le melemo e totobetseng le menyetla ea nts'etsopele mabapi le tšireletso ea tikoloho, boleng le nts'etsopele ea theknoloji.

---------------------------------------------------Mohloli oa boitsebiso ROUYIN JISHU WENDA

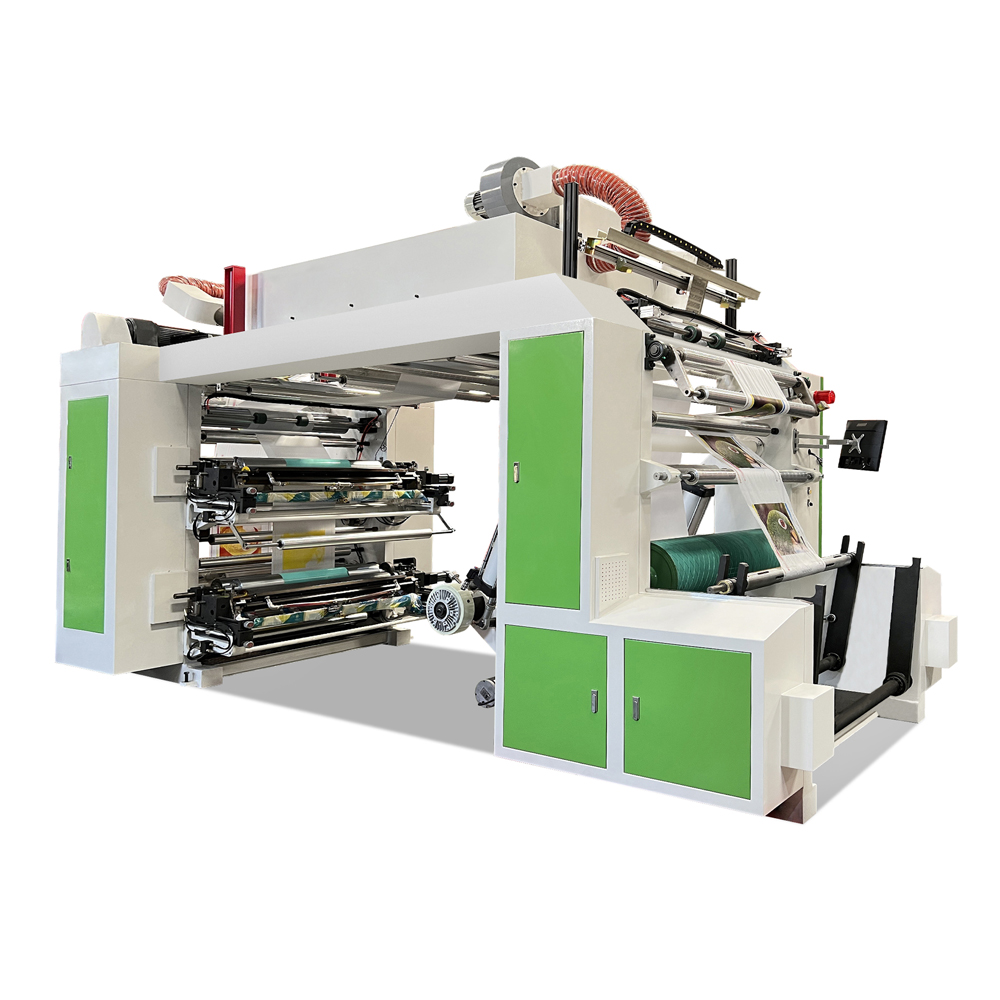

- Sebopeho sa mochini: Sebelisa drive e kgolo ya gear mme o ngodise mmala o nepahetseng haholoanyane.

- Sebopeho se senyenyane. Likarolo tsa mochini li ka fapanyetsana ho etsa maemo a tloaelehileng 'me li bonolo ho li fumana. 'Me re khetha moralo o tlase oa ho khohlela.

- Poleiti e bonolo haholo. E ka boloka nako e ngata le ho bitsa chelete e nyane.

- Kgatelelo ya khatiso e nyane. E ka fokotsa matlakala mme ya etsa hore tshebeletso e phele nako e telele.

- Ho hatisa mefuta e mengata ea thepa ho kenyelletsa li-reel tse fapaneng tse tšesaane tsa filimi.

- Amohela rolara ea Ceramic Anilox ea boleng bo holimo ho eketsa phello ea khatiso.

- Amohela lisebelisoa tsa motlakase tse tsoang kantle ho naha ho etsa hore taolo ea potoloho ea motlakase e be le botsitso le polokeho.

- Foreime ea Mochini: Poleiti ea tšepe e teteaneng ea 75MM. Ha e thothomele ka lebelo le phahameng 'me e na le bophelo bo bolelele ba ts'ebeletso.

- Sebopeho sa mochini: Sistimi ea phetiso ea li-gear e nepahetseng haholo, Sebelisa drive e kholo ea li-gear 'me u ngolise' mala o nepahetseng haholoanyane.

- Sebopeho se senyenyane. Likarolo tsa mochini li ka fapanyetsana ho etsa maemo a tloaelehileng 'me li bonolo ho li fumana. 'Me re khetha moralo o tlase oa ho khohlela.

- Poleiti e bonolo haholo. E ka boloka nako e ngata le ho bitsa chelete e nyane.

- Kgatelelo ya khatiso e nyane. E ka fokotsa matlakala mme ya etsa hore tshebeletso e phele nako e telele.

- Ho hatisa mefuta e mengata ea thepa ho kenyelletsa li-reel tse fapaneng tse tšesaane tsa filimi.

- Amohela disilindara tse nepahetseng haholo, dirolara tse tataisang le rolara ya boleng bo hodimo ya Ceramic Anilox ho eketsa phello ya ho hatisa.

- Amohela lisebelisoa tsa motlakase tse tsoang kantle ho naha ho etsa hore taolo ea potoloho ea motlakase e be le botsitso le polokeho.

- Foreime ea Mochini: Poleiti ea tšepe e teteaneng ea 75MM. Ha e thothomele ka lebelo le phahameng 'me e na le bophelo bo bolelele ba ts'ebeletso.

- Mahlakore a Mabedi 6+0; 5+1; 4+2; 3+3

- Taolo ea tataiso ea webo ka boiketsetso, bohale le boiketsetso

- Re ka boela ra iketsetsa mochini ho latela litlhoko tsa bareki

- Sebopeho sa mochini: Sebelisa drive e kgolo ya gear mme o ngodise mmala o nepahetseng haholoanyane.

- Sebopeho se senyenyane. Likarolo tsa mochini li ka fapanyetsana ho etsa maemo a tloaelehileng 'me li bonolo ho li fumana. 'Me re khetha moralo o tlase oa ho khohlela.

- Poleiti e bonolo haholo. E ka boloka nako e ngata le ho bitsa chelete e nyane.

- Kgatelelo ya khatiso e nyane. E ka fokotsa matlakala mme ya etsa hore tshebeletso e phele nako e telele.

- Ho hatisa mefuta e mengata ea thepa ho kenyelletsa li-reel tse fapaneng tse tšesaane tsa filimi.

- Amohela rolara ea Ceramic Anilox ea boleng bo holimo ho eketsa phello ea khatiso.

- Amohela lisebelisoa tsa motlakase tse tsoang kantle ho naha ho etsa hore taolo ea potoloho ea motlakase e be le botsitso le polokeho.

- Foreime ea Mochini: Poleiti ea tšepe e teteaneng ea 75MM. Ha e thothomele ka lebelo le phahameng 'me e na le bophelo bo bolelele ba ts'ebeletso.

Nako ea poso: Pherekhong-31-2022