Mochini o mocha oa khatiso oa 8 olor flexographic ci o nang le lebelo le phahameng o sa khaotseng oa li-steishene tse peli o lokollang/o khutlisetsang morao o sa khaotseng, o etselitsoeng khatiso ea filimi ea polasetiki ka ho khetheha. O sebelisa theknoloji ea silindara ea maikutlo a bohareng ho netefatsa tlhahiso e nepahetseng le e sebetsang hantle. O hlomelitsoe ka taolo e tsoetseng pele ea othomathiki le sistimi e tsitsitseng ea khatello, mochini ona o fihlela litlhoko tsa khatiso e tsoelang pele e potlakileng haholo, e leng se ntlafatsang haholo katleho ea tlhahiso.

● Litlhaloso tsa Tekheniki

| Mohlala | CHCI8-600E-S | CHCI8-800E-S | CHCI8-1000E-S | CHCI8-1200E-S |

| Bophara ba Web bo boholo | 700mm | 900mm | 1100mm | 1300mm |

| Bophara ba Khatiso bo Holimo | 600mm | 800mm | 1000mm | 1200mm |

| Lebelo le Phahameng la Mochini | 350m/motsotso | |||

| Lebelo le Phahameng la ho Hatisa | 300m/motsotso | |||

| Boholo. Fokotsa/Khutlisa Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Mofuta oa Drive | Moropa o bohareng o nang le Gear drive | |||

| Poleiti ea Photopolymer | Ho tla hlalosoa | |||

| Enke | Enke ea motheo oa metsi kapa enke ea solvent | |||

| Bolelele ba Khatiso (pheta) | 350mm-900mm | |||

| Mefuta e fapaneng ea Li-substrate | LDPE, LLDPE, HDPE, BOPP, CPP, OPP,PET, Nylon, | |||

| Phepelo ea Motlakase | Motlakase 380V. 50 HZ.3PH kapa e tla boleloa | |||

● Selelekela sa Video

● Likarolo tsa Mochini

1.Tlhahiso e Tsoelang Pele e Bokgoni bo Phahameng Ntle le Nako ea ho se Fumane Mosebetsi:

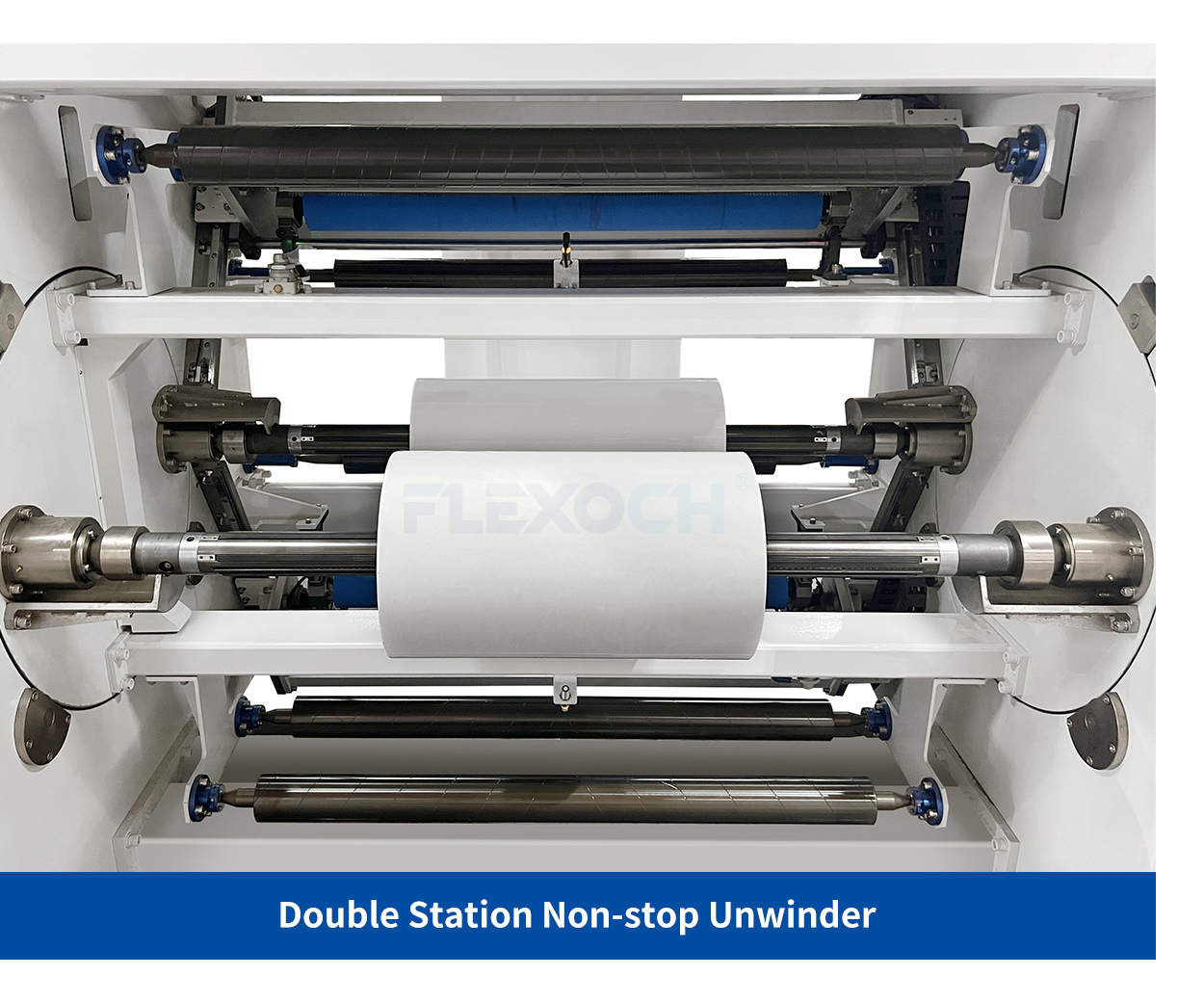

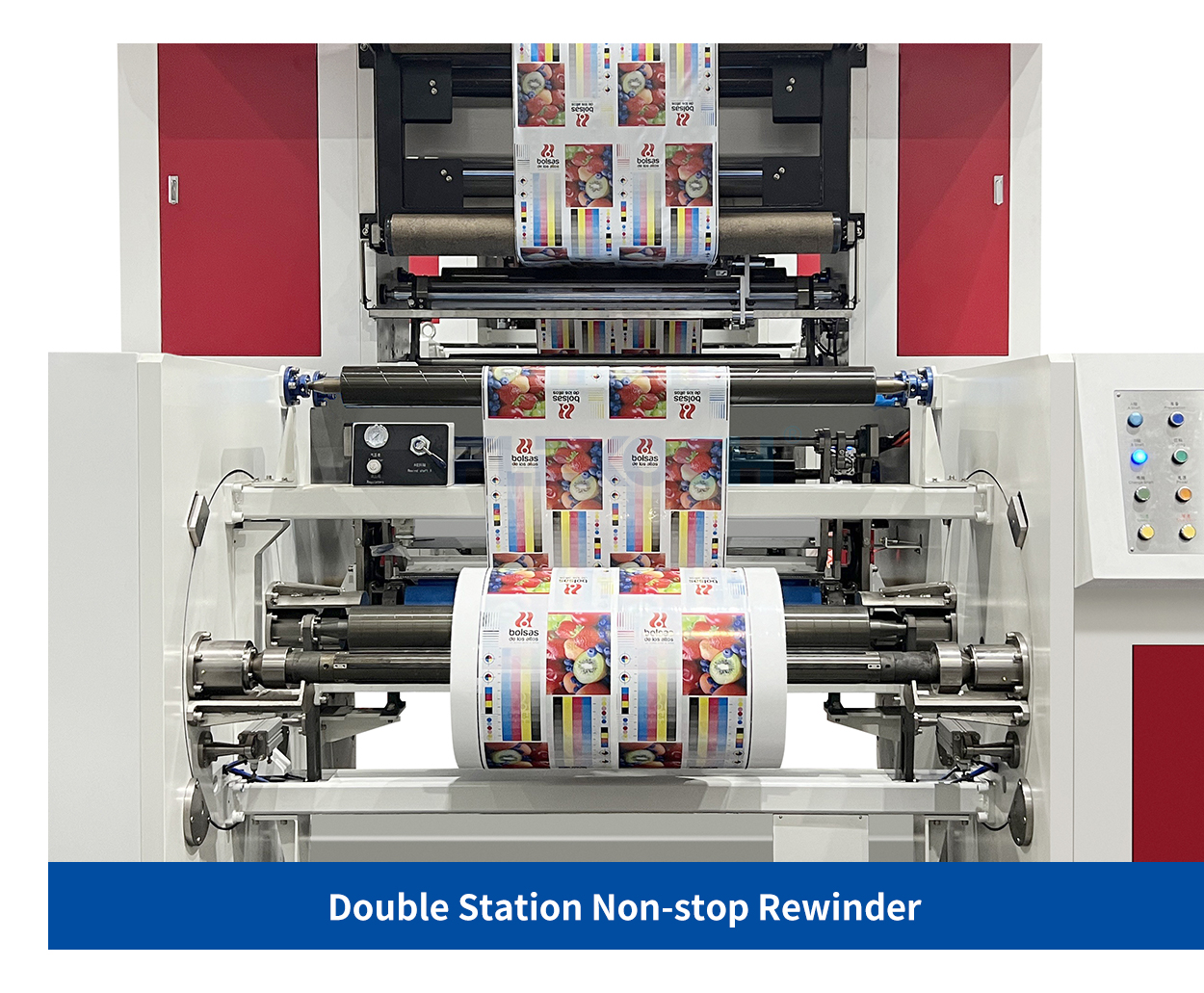

Senamochini oa khatiso oa cie na le sistimi e ikhethang ea ho phutholoha/ho kgutlisa morao ya diteishene tse pedi, e nolofalletsang diphetoho tsa ho phutholla ka boiketsetso nakong ya tshebetso e potlakileng. Sena se fedisa moedi wa setso wa ho hloka ho kwalwa ha mochini bakeng sa diphetoho tsa ho phutholla. Moralo o motjha wa mechini, o kopantsweng le sistimi ya taolo ya kgatello e nepahetseng, o netefatsa phetoho e boreleli le e tsitsitseng ya ho phutholla, o fokotsa tshenyo ya thepa ka tekanyo e kgolo. Sena se ntlafatsa tlholisano ya mmaraka ya dikgwebo tsa ho hatisa dipakete haholo.

2.Boleng bo Phahameng ba ho Hatisa bo Tsitsitseng: Mochini oa khatiso oa CI o sebelisa sebopeho sa silindara sa Central Impression (CI) se kopantsoeng le sistimi ea ho khanna ka nepo ea gear, o netefatsa ho nepahala ha ngoliso ka hare ho ± 0.1 mm ho pholletsa le li-unit tsohle tsa mebala. Sistimi e ntlafalitsoeng ea ho fana ka enke le lisebelisoa tsa ho lokisa khatello li tiisa matheba a bohale, a felletseng le ho ikatisa ha 'mala ka mokhoa o ts'oanang, o tsitsitseng. Sistimi ea ho omisa e entsoeng ka boqhetseke e amohela mefuta e fapaneng ea enke, e netefatsa tlhahiso e tsitsitseng le ea boleng bo holimo e hatisitsoeng.

3.Sistimi ea Taolo e Tsoetseng Pele e Ntlafatsa Phihlelo ea Mosebelisi: Mochini oa khatiso oa ci flexo o na le sistimi ea taolo ea profeshenale, basebetsi ba ka lekola boleng ba khatiso ka nako ea sebele ka video ea qeto e phahameng. Sebopeho sa taolo se bonolo se nolofatsa ts'ebetso ea ho seta liparamente, ka data ea tlhahiso ea bohlokoa e bonts'oang ka ho hlaka. Mesebetsi e felletseng ea tlhahlobo ea liphoso e thusa ho tsebahatsa bothata ka potlako, e leng se eketsang katleho ea tlhahiso haholo.

4.Sebopeho se Tenyetsehang bakeng sa Litlhoko tse Fapaneng:

E na le meralo e fapaneng, mochine ona oa khatiso oa ci flexo o lumella metsoako e tenyetsehang ea li-unit tse 4 ho isa ho tse 8 tsa khatiso, o nolofalletsang phetoho e potlakileng lipakeng tsa mesebetsi e fapaneng ea khatiso. Moralo oa eona o tiileng oa mechini o sebetsana le mefuta e mengata ea lifilimi tsa polasetiki ho tloha ho li-micron tse 10 ho isa ho tse 150, ho kenyeletsoa PE, PP, PET, le tse ling. E fana ka liphetho tse ikhethang tsa khatiso bakeng sa mongolo o bonolo le litšoantšo tse rarahaneng tsa mebala e mengata, e fihlelang litlhoko tse fapaneng tsa bareki ba fapaneng.

● Dispaly ea Lintlha

● Mohlala oa ho Hatisa

Nako ea poso: Phuptjane-27-2025