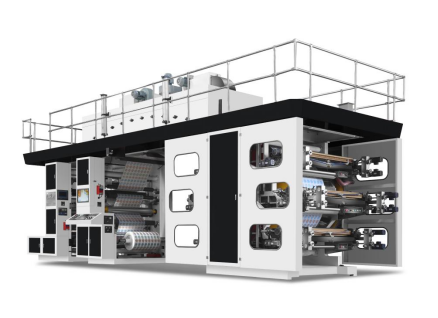

Drum e Bohareng ea Cl Flexo Printing Press e ka sebelisoa e le karolo e tsitsitseng ea yuniti e laolang khatello. Ntle le ts'ebetso ea 'mele o ka sehloohong, boemo ba eona bo otlolohileng bo tsitsitse ebile bo tsitsitse. Karolo e fetohang sehlopheng sa mebala ea khatiso e haufi kapa e arohane le rolara e bohareng. Finyella taolo ea khatello ea thepa ea khatiso. Moqomo o bohareng o tsamaisoa ka kotloloho ke motor torque ea Siemens. Ntho e totobetseng ka ho fetisisa ke hore motlakase oa servo oa setso o nang le lebokose la ho fokotsa o tlosoa. Monyetla oa moralo oa koloi ena e tobileng ke: e amanang le motsotso o monyenyane oa inertia, phetisetso e kholo ea torque, tsamaiso ea ho pholisa metsi e ka Ntlafatsoa ke matla a lekantsoeng, matla a mangata a mangata, karabelo e phahameng ea matla le ho nepahala ho phahameng ho hatisa.

● Litlhaloso tsa Theknoloji

| Mohlala | CHCI6-600E-S | CHCI6-800E-S | CHCI6-1000E-S | CHCI6-1200E-S |

| Max. Bophara ba Web | 700 limilimithara | 900 limilimithara | 1100mm | 1300 limilimithara |

| Max. Bophara ba Khatiso | 600 limilimithara | 800 limilimithara | 1000mm | 1200 limilimithara |

| Max. Lebelo la Mochini | 350m/min | |||

| Max. Lebelo la ho Hatisa | 300m/min | |||

| Max. Fokotsa/Khutlisa Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Mofuta oa Drive | Moropa o bohareng o nang le Gear drive | |||

| Letlapa la Photopolymer | Ho hlalosoa | |||

| Enke | Motheo oa metsi enke ea oli ea mohloaare | |||

| Bolelele ba Khatiso (pheta) | 350mm-900mm | |||

| Mefuta e fapaneng ea li-substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Phepelo ea Motlakase | Voltage 380V.50 HZ.3PH kapa e tla hlalosoa | |||

● Kenyelletso ea Video

●Uwinding unit

Ci flexo mochini o qetang karolo o amohela sebopeho se ikemetseng sa turret bidirectional rotation dual-axis dual-station structure, e ka fetolang thepa ntle le ho emisa mochini. Ho bonolo ho sebetsa, ho boloka nako le lisebelisoa; ho phaella moo, moralo oa ho laola ka mokhoa o itekanetseng oa PLC o ka fokotsa tšitiso ea batho ka katleho le ho ntlafatsa ho nepahala ha ho itšeha; Moralo oa ho lemoha o ikemetseng oa bophara ba moqolo o qoba mefokolo ea ho kenya letsoho ka letsoho ha o fetola meqolo. Sesebelisoa sa ho lemoha bophara ba roll se sebelisetsoa ho lemoha ka bohona bophara ba moqolo o mocha. Moralo oa sisteme ea ho lemoha tsitsipano e laola ho potoloha ho ea pele le ka morao ha enjene, e ka laolang tsitsipano ea sistimi ka nepo.

●Setsi sa khatiso

Sebopeho se utloahalang sa lirolara se thusa hore thepa ea filimi e tsamaee hantle; moralo oa phetoho ea poleiti ea sleeve o ntlafatsa haholo lebelo la phetoho ea poleiti mme o netefatsa katleho e phahameng haholo ea khatiso; scraper e koetsoeng e fokotsa mouoane oa solvent le ho tsitsisa viscosity, e sa qobeng ho phatloha ha enke feela, empa hape e ka netefatsa viscosity e tsitsitseng ea khatiso; ceramic anilox roller e na le ts'ebetso e phahameng ea phetisetso, enke e lekana ebile e boreleli, 'me e tiile ebile e tšoarella; sebopeho sa mochine oa motho se sebelisana le PLC ho laola ka bohona ho phahamisa ka mor'a ho beha data.

● Khutlela morao

Dual-axis dual-motor drive, phetoho ea thepa e sa emeng, ts'ebetso e bonolo, ho boloka nako le thepa; PLC le sesebelisoa sa photoelectric se laola le ho lemoha boemo bo nepahetseng ba ho itšeha, ho fokotsa liphoso le mathata a bakoang ke ts'ebetso ea matsoho, le ho ntlafatsa katleho ea ho itšeha; moralo oa li-buffer roller ka katleho o qoba tšusumetso e feteletseng nakong ea phetisetso ea theipi mme o fokotsa ho fetoha ha tsitsipano; mokhoa oa ho fetola moqolo o laoloa ke lenaneo la PLC ho netefatsa hore o lumellana le lebelo la moeti; foreimi e ikemetseng ea rotary e na le ts'ebetso e phahameng ea ts'ebetso 'me e bonolo ho e sebetsa; the winding The taper tension e amohela li-close-loop feedback automatic control ho netefatsa tsitsipano e tsitsitseng ka hare le ka ntle ho moqolo le ho thibela wrinkles linthong tse kolobisitsoeng tsa filimi.

●Sistimi ea ho omisa bohareng

Mokhoa oa ho omisa o na le sebopeho sa masala a sebetsang hantle le a tlaase, 'me sehlahisoa se na le masala a tlaase a solvent; onto e amohela moralo o mobe oa khatello ho thibela moea o chesang hore o se ke oa tsoa, 'me mocheso o laoloa ka bo eona ka nepo e phahameng; mocheso o tlase le molumo o phahameng oa moea li ka etsa kharafu ea moea, e bolokang matla haholo.

Nako ea poso: May-20-2024