Mochine oa khatiso oa ci flexo oa mebala oa 4 o tsepamisitsoe holim'a moqomo o bohareng oa maikutlo 'me o na le lihlopha tse pota-potileng lihlopha tse mebala-bala ho etsa bonnete ba hore phetisetso ea lisebelisoa tse otlollang zero le ho finyella ho nepahala ha ultra-high overprint. E etselitsoe ka ho khetheha bakeng sa li-substrates tse holofetseng habonolo tse kang lifilimi le li-foil tsa aluminium, li na le lebelo la khatiso le potlakileng le le tsitsitseng, 'me li kopanya li-inks tse nang le tikoloho le mekhoa e bohlale ea ho laola, ho nahanela tlhahiso e sebetsang hantle le litlhoko tse tala. Ke tharollo e ncha tšimong ea ho paka ka mokhoa o nepahetseng haholo.

● Technical Parameters

| Mohlala | CHCI4-600J-S | CHCI4-800J-S | CHCI4-1000J-S | CHCI4-1200J-S |

| Max. Bophara ba Web | 650 limilimithara | 850 limilimithara | 1050 limilimithara | 1250 limilimithara |

| Max. Bophara ba Khatiso | 600 limilimithara | 800 limilimithara | 1000mm | 1200 limilimithara |

| Max. Lebelo la Mochini | 250m/min | |||

| Max. Lebelo la ho Hatisa | 200m/min | |||

| Max. Fokotsa/Khutlisa Dia. | Φ800mm/Φ1000mm/Φ1200mm | |||

| Mofuta oa Drive | Moropa o bohareng o nang le Gear drive | |||

| Letlapa la Photopolymer | Ho hlalosoa | |||

| Enke | Enke ea motheo ea metsi kapa enke ea solvent | |||

| Bolelele ba Khatiso (pheta) | 350mm-900mm | |||

| Mefuta e fapaneng ea li-substrates | LDPE, LLDPE, HDPE, BOPP, CPP, PET, Nylon, | |||

| Phepelo ea Motlakase | Motlakase oa 380V. 50 HZ.3PH kapa e tla hlalosoa | |||

● Litšobotsi tsa Mochine

Mochine oa khatiso oa 1.Ci flexo ke mechine ea khatiso e tsoetseng pele haholo le e sebetsang hantle e fanang ka melemo e mengata ho lik'hamphani tsa indasteri ea ho paka. Ka ts'ebetso ea eona ea lebelo le holimo le boleng bo holimo ba khatiso, mochini o khona ho hlahisa likhatiso tse hlakileng le tse hlakileng mefuteng e fapaneng ea thepa ea ho paka.

2.E 'ngoe ea melemo e ka sehloohong ea ho sebelisa mochine oa khatiso oa Ci flexo ke hore lihlopha tsohle tsa khatiso li hlophisitsoe ka radially ho pota-pota sekontiri se le seng sa maikutlo a bohareng, se nang le thepa e tsamaisoang hammoho le cylinder hohle, ho felisa deformation e otlolohileng e bakoang ke ho fetisoa ha lihlopha tse ngata, ho netefatsa khatiso e nepahetseng le e nepahetseng, le ho hatisoa ha boleng bo phahameng nako le nako.

3.Mochine oa khatiso oa cI flexo o boetse o na le chelete e ngata ebile o na le tikoloho. Mochine o hloka tlhokomelo e fokolang le ho seta ts'ebetso, e leng ho fokotsang nako le ho eketsa tlhahiso. Ntle le moo, e sebelisa li-inks tse thehiloeng metsing le lisebelisoa tse baballang tikoloho, e kopana le litekanyetso tsa polokeho ea liphutheloana tsa lijo mme e ka thusa lik'hamphani ho fokotsa khabone ea tsona. Ke sesupo sa popontshwa ya tekhenoloji mafapheng a dijo, meriana le diphutheloana tse baballang tikoloho.

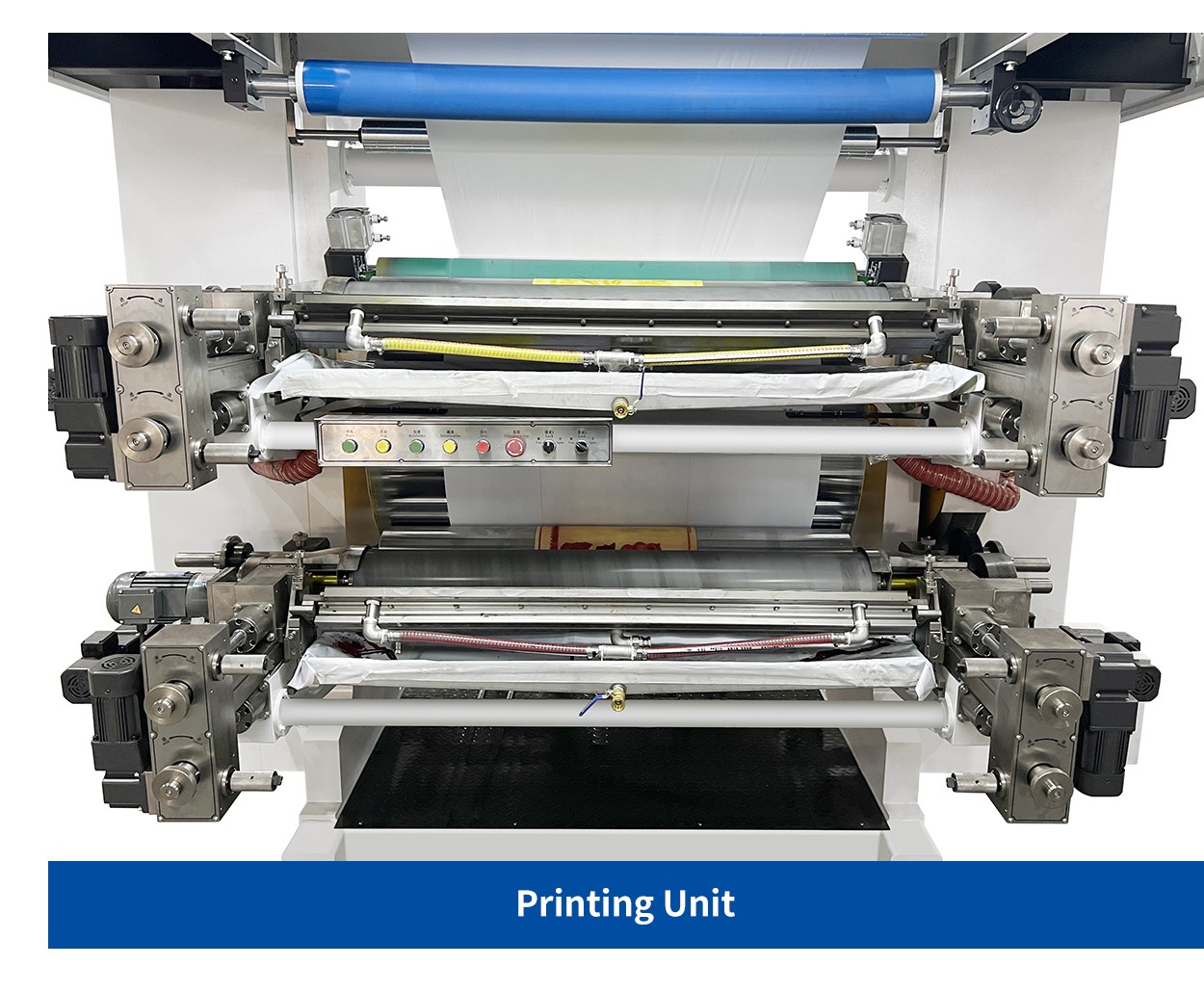

●Details Dispaly

● Mohlala oa khatiso

Nako ea poso: Mar-06-2025