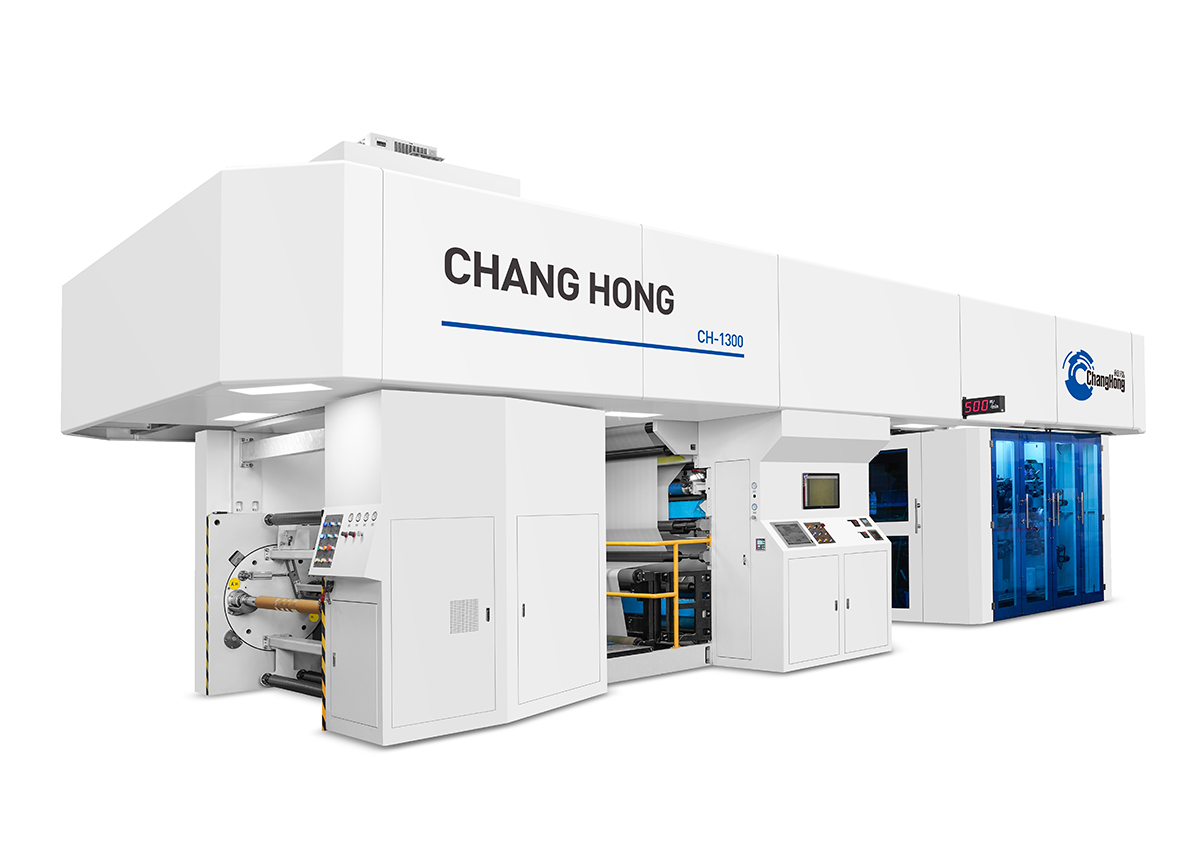

Theko ea Lihlahisoa tsa Feme ea fektheri ka Mohala Modular Printing Petal Flexo Stciker Labels Roll to Roll Flexographic Printing Machine

Theko ea Lihlahisoa tsa Feme ea fektheri ka Mohala Modular Printing Petal Flexo Stciker Labels Roll to Roll Flexographic Printing Machine

Re ipapisitse le matla a matle a tekheniki 'me re lula re theha mahlale a morao-rao ho khotsofatsa tlhoko ea Theko ea Lihlahisoa tsa Factory Supply Wholesale Line Modular Printing Petal Flexo Stciker Labels Roll to Roll Flexographic Printing Machine, Ka ho sebetsa ka thata hore mosebetsi o etsoe, hangata re 'nile ra ba ka pele-pele ho nchafatsa lihlahisoa tsa theknoloji. Re bile balekane ba tikoloho eo u ka itšetlehang ka eena. Ikopanye le rona kajeno bakeng sa lintlha tse ling!

Re itšetlehile ka matla a matla a tekheniki 'me re lula re theha mahlale a tsoetseng pele ho khotsofatsa tlhoko eaMochini oa khatiso oa Flexografica oa 1 le Mebala e 8 ea Mochine oa Khatiso oa Flexo, Ntle le matla a matla a tekheniki, re boetse re kenyelletsa lisebelisoa tse tsoetseng pele bakeng sa tlhahlobo le ho tsamaisa taolo e thata. Basebetsi bohle ba k'hamphani ea rona ba amohela metsoalle ea lapeng le kantle ho naha hore e tle bakeng sa maeto le khoebo motheong oa tekano le melemo e kopaneng. Haeba u thahasella efe kapa efe ea lintho tsa rona, hopola ho ikutloa u lokolohile ho ikopanya le rona bakeng sa khotheishene le lintlha tsa sehlahisoa.

lintlha tsa tekheniki

| Mohlala | CH6-600H | CH6-800H | CH6-1000H | CH6-1200H |

| Max. Boleng ba webo | 650 limilimithara | 850 limilimithara | 1050 limilimithara | 1250 limilimithara |

| Max. Boleng ba khatiso | 600 limilimithara | 800 limilimithara | 1000mm | 1200 limilimithara |

| Max. Lebelo la Mochini | 120m/min | |||

| Lebelo la ho Hatisa | 100m/min | |||

| Max. Fokotsa/Khutlisa Dia. | φ800mm | |||

| Mofuta oa Drive | Ho tsamaisa lebanta la nako | |||

| Botenya ba poleiti | Photopolymer poleiti 1.7mm kapa 1.14mm (kapa e lokela ho boleloa) | |||

| Enke | Enke ea motheo ea metsi kapa enke ea solvent | |||

| Bolelele ba khatiso (pheta) | 300mm-1000mm | |||

| Mefuta e fapaneng ea li-substrates | LDPE; LLDPE; HDPE; BOPP, CPP, PET; Nylon, PAPER, NONWOVEN | |||

| Phepelo ea motlakase | Motlakase oa 380V. 50 HZ.3PH kapa e tla hlalosoa | |||

Likarolo tsa Mochini

- Mechini ea khatiso ea stack flexo e sebelisoa haholo-holo bakeng sa khatiso ka thepa ea ho paka e tenyetsehang joalo ka lifilimi tsa polasetiki, pampiri le masela a sa lohiloeng.

- Mechini ena e na le tlhophiso e emeng moo likarolo tsa khatiso li kenngoeng ka holim'a tse ling.

- Karolo e 'ngoe le e' ngoe e na le rolara ea anilox, lehare la ngaka, le silindara ea poleiti e sebetsang 'moho ho fetisetsa enke holim'a substrate e hatisoang.

- Mechine ea khatiso ea stack flexo e tsebahala ka lebelo la eona le phahameng la khatiso le ho nepahala.

- Li fana ka boleng bo botle ba khatiso bo nang le ho thothomela ha mebala e phahameng le ho hlaka.

- Mechini ena e sebetsa ka mokhoa o fapaneng 'me e ka sebelisoa ho hatisa meralo e fapaneng, ho kenyeletsoa mongolo, litšoantšo le litšoantšo.

- Li hloka nako e fokolang ea ho seta, e leng se etsang hore e be khetho e nepahetseng bakeng sa lipampiri tse khutšoane tsa khatiso.

- Mechine ea khatiso ea stack flexo e bonolo ho e hlokomela le ho sebetsa, ho fokotsa nako ea ho theoha le litšenyehelo tsa tlhahiso.

Lintlha Dispaly

mohlala

Ho paka le ho Romela

LBH

P: Mochini oa khatiso oa stack flexo ke eng?

A: Mochine oa khatiso oa flexo oa mofuta oa stack ke mofuta oa mochine oa khatiso o sebelisetsoang khatiso ea boleng bo phahameng ka thepa e sa tšoaneng e kang pampiri, polasetiki le foil. E sebelisa mochine oa stack moo seteishene se seng le se seng sa mebala se pakoang ka holim'a se seng ho fihlela mebala e lakatsehang.

P: Ke lintlha life tseo ke lokelang ho li nahana ha ke khetha mochine oa khatiso oa stack flexo?

A: Ha u khetha mochine oa khatiso oa stack flexo, lintlha tse lokelang ho nahanoa li kenyelletsa palo ea lihlopha tsa khatiso, bophara le lebelo la mochine, mefuta ea li-substrates tseo u ka li hatisang.

P: Ke palo e kholo ea mebala efe e ka hatisoang ka khatiso ea stack flexo?

A: Palo e phahameng ea mebala e ka hatisoang ho sebelisoa khatiso ea stack flexo e itšetlehile ka mochine o khethehileng oa khatiso le ho seta poleiti, empa hangata e ka tloha ho 4/6/8 mebala.

Re ipapisitse le matla a matle a tekheniki 'me re lula re theha mahlale a morao-rao ho khotsofatsa tlhoko ea Theko ea Lihlahisoa tsa Factory Supply Wholesale Line Modular Printing Petal Flexo Stciker Labels Roll to Roll Flexographic Printing Machine, Ka ho sebetsa ka thata hore mosebetsi o etsoe, hangata re 'nile ra ba ka pele-pele ho nchafatsa lihlahisoa tsa theknoloji. Re bile balekane ba tikoloho eo u ka itšetlehang ka eena. Ikopanye le rona kajeno bakeng sa lintlha tse ling!

Phepelo ea FemeMochini oa khatiso oa Flexografica oa 1 le Mebala e 8 ea Mochine oa Khatiso oa Flexo, Ntle le matla a matla a tekheniki, re boetse re kenyelletsa lisebelisoa tse tsoetseng pele bakeng sa tlhahlobo le ho tsamaisa taolo e thata. Basebetsi bohle ba k'hamphani ea rona ba amohela metsoalle ea lapeng le kantle ho naha hore e tle bakeng sa maeto le khoebo motheong oa tekano le melemo e kopaneng. Haeba u thahasella efe kapa efe ea lintho tsa rona, hopola ho ikutloa u lokolohile ho ikopanya le rona bakeng sa khotheishene le lintlha tsa sehlahisoa.