Theko ea Fektheri Bakeng sa Mochini oa ho Hatisa oa Flexo oa 4 6 8 oa 'Mala oa Central Drum PE

Theko ea Fektheri Bakeng sa Mochini oa ho Hatisa oa Flexo oa 4 6 8 oa 'Mala oa Central Drum PE

Ka lebaka la tšehetso ea sehlopha sa IT se tsoetseng pele haholo le se ikhethang, re ka fana ka tšehetso ea tekheniki mabapi le tšebeletso ea pele ho thekiso le kamora thekiso bakeng sa Theko ea Fektheri Bakeng sa Mochini oa ho Hatisa oa Flexo oa Mebala e Bohareng ea Drum PE oa 4 6 8, Re tla etsa sohle se matleng a rona ho khotsofatsa litlhoko tsa hau 'me re ntse re batla ka tieo ho fumana lerato le molemo la k'hamphani le uena!

Re tšehelitsoe ke sehlopha sa IT se tsoetseng pele haholo le se ikhethang, re ka fana ka tšehetso ea tekheniki tšebeletsong ea pele ho thekiso le ea kamora thekiso bakeng saMochini oa ho Hatisa oa Flexo le Liprinta tsa Flexographic, Re loanela bokhabane, ntlafatso e sa khaotseng le boqapi, re ikemiselitse ho re etsa "tšepo ea bareki" le "khetho ea pele ea bafepedi ba lisebelisoa tsa mechini ea boenjiniere". Re khethe, re arolelana boemo ba bohle!

litlhaloso tsa tekheniki

| Mohlala | CHCI4-600J-Z | CHCI4-800J-Z | CHCI4-1000J-Z | CHCI4-1200J-Z |

| Bophara ba Web bo boholo | 650mm | 850mm | 1050mm | 1250mm |

| Bophara ba Khatiso bo Holimo | 600mm | 800mm | 1000mm | 1200mm |

| Lebelo le Phahameng la Mochini | 250m/motsotso | |||

| Lebelo le Phahameng la ho Hatisa | 200m/motsotso | |||

| Boholo. Fokotsa/Khutlisa Dia. | Φ1200mm/Φ1500mm | |||

| Mofuta oa Drive | Moropa o bohareng o nang le Gear drive | |||

| Poleiti ea Photopolymer | Ho tla hlalosoa | |||

| Enke | Enke ea motheo oa metsi kapa enke ea solvent | |||

| Bolelele ba Khatiso (pheta) | 350mm-900mm | |||

| Mefuta e fapaneng ea Li-substrate | Pampiri, e seng e lohiloeng, kopi ea pampiri | |||

| Phepelo ea Motlakase | Motlakase 380V. 50 HZ.3PH kapa e tla boleloa | |||

Selelekela sa Video

Likarolo tsa Mochini

1. Lebelo le phahameng la ho hatisa: Mochini ona o khona ho hatisa ka lebelo le phahameng, e leng se fetolelang tlhahiso e phahameng ea thepa e hatisitsoeng ka nako e khuts'oane.

2. Ho tenyetseha ha khatiso: Ho tenyetseha ha khatiso ea flexographic ho lumella tšebeliso ea mefuta e fapaneng ea thepa e ke keng ea hatisoa ka mekhoa e meng. Ho phaella moo, liparamente le litekanyo le tsona li ka fetoloa ho etsa liphetoho tse potlakileng khatisong le tlhahisong.

3. Boleng bo phahameng ba ho hatisa: Ho hatisa pampiri ea ci ka mokhoa o feto-fetohang ho fana ka boleng bo phahameng ba ho hatisa ho feta mekhoa e meng ea ho hatisa, hobane enke e metsi e sebelisoa ho fapana le li-toners kapa li-cartridge tsa ho hatisa.

4. Litšenyehelo tse tlase tsa tlhahiso: Mochini ona o na le litšenyehelo tse tlase tsa tlhahiso ha o bapisoa le mekhoa e meng ea khatiso. Ho phaella moo, tšebeliso ea enke e thehiloeng metsing e fokotsa litšenyehelo le ho ntlafatsa botsitso ba ts'ebetso.

5. Ho tšoarella ha nako e telele ha hlobo ea flexographic: Mefuta ea flexographic e sebelisoang mochining ona e tšoarella ho feta e sebelisoang mekhoeng e meng ea khatiso, e leng se etsang hore litšenyehelo tsa tlhokomelo li be tlase.

Dintlha tsa Dispaly

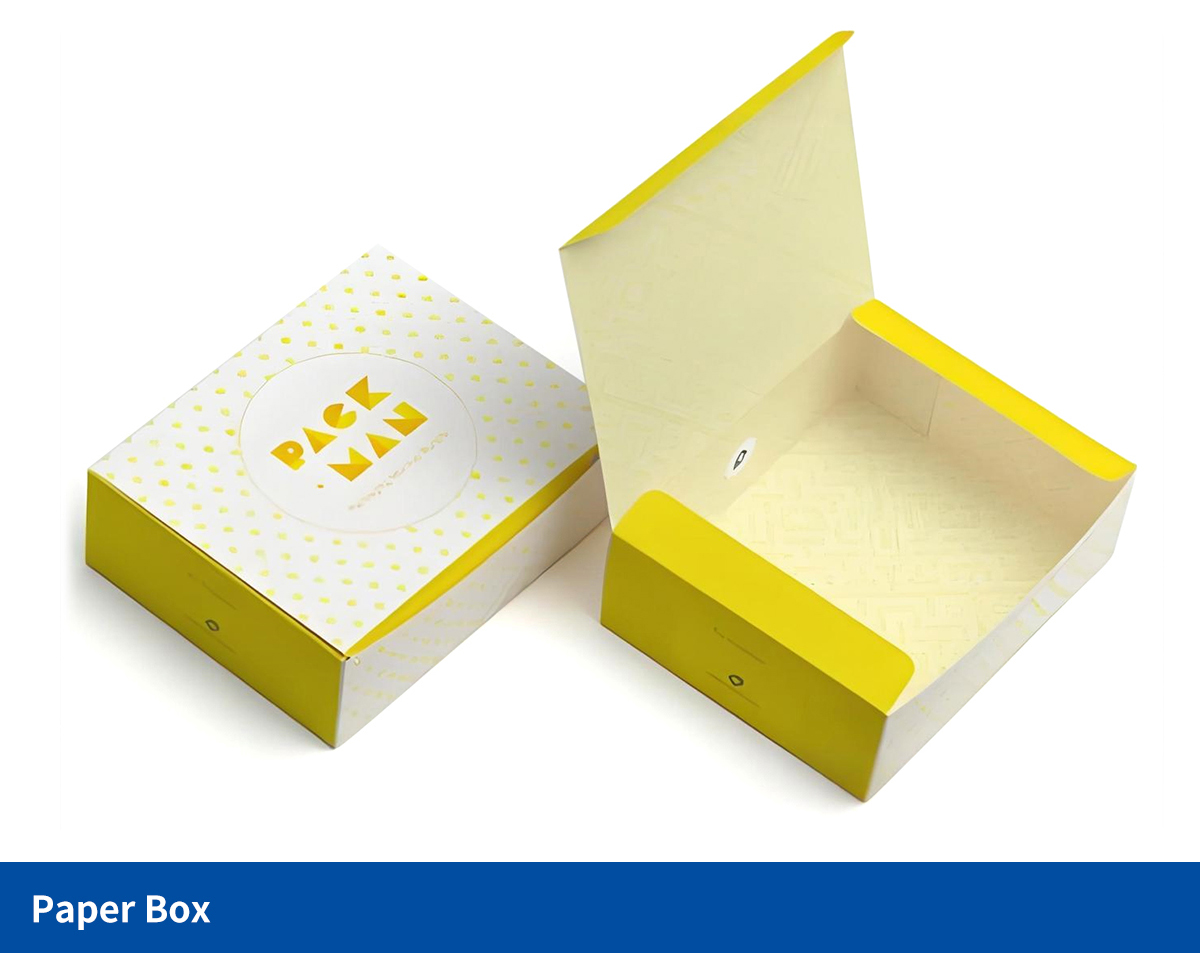

sampole

Ho paka le ho tlisa thepa

Ka lebaka la tšehetso ea sehlopha sa IT se tsoetseng pele haholo le se ikhethang, re ka fana ka tšehetso ea tekheniki mabapi le tšebeletso ea pele ho thekiso le kamora thekiso bakeng sa Theko ea Fektheri Bakeng sa Mochini oa ho Hatisa oa Flexo oa Mebala e Bohareng ea Drum PE oa 4 6 8, Re tla etsa sohle se matleng a rona ho khotsofatsa litlhoko tsa hau 'me re ntse re batla ka tieo ho fumana lerato le molemo la k'hamphani le uena!

Theko ea Fektheri Bakeng saMochini oa ho Hatisa oa Flexo le Liprinta tsa Flexographic, Re loanela bokhabane, ntlafatso e sa khaotseng le boqapi, re ikemiselitse ho re etsa "tšepo ea bareki" le "khetho ea pele ea bafepedi ba lisebelisoa tsa mechini ea boenjiniere". Re khethe, re arolelana boemo ba bohle!