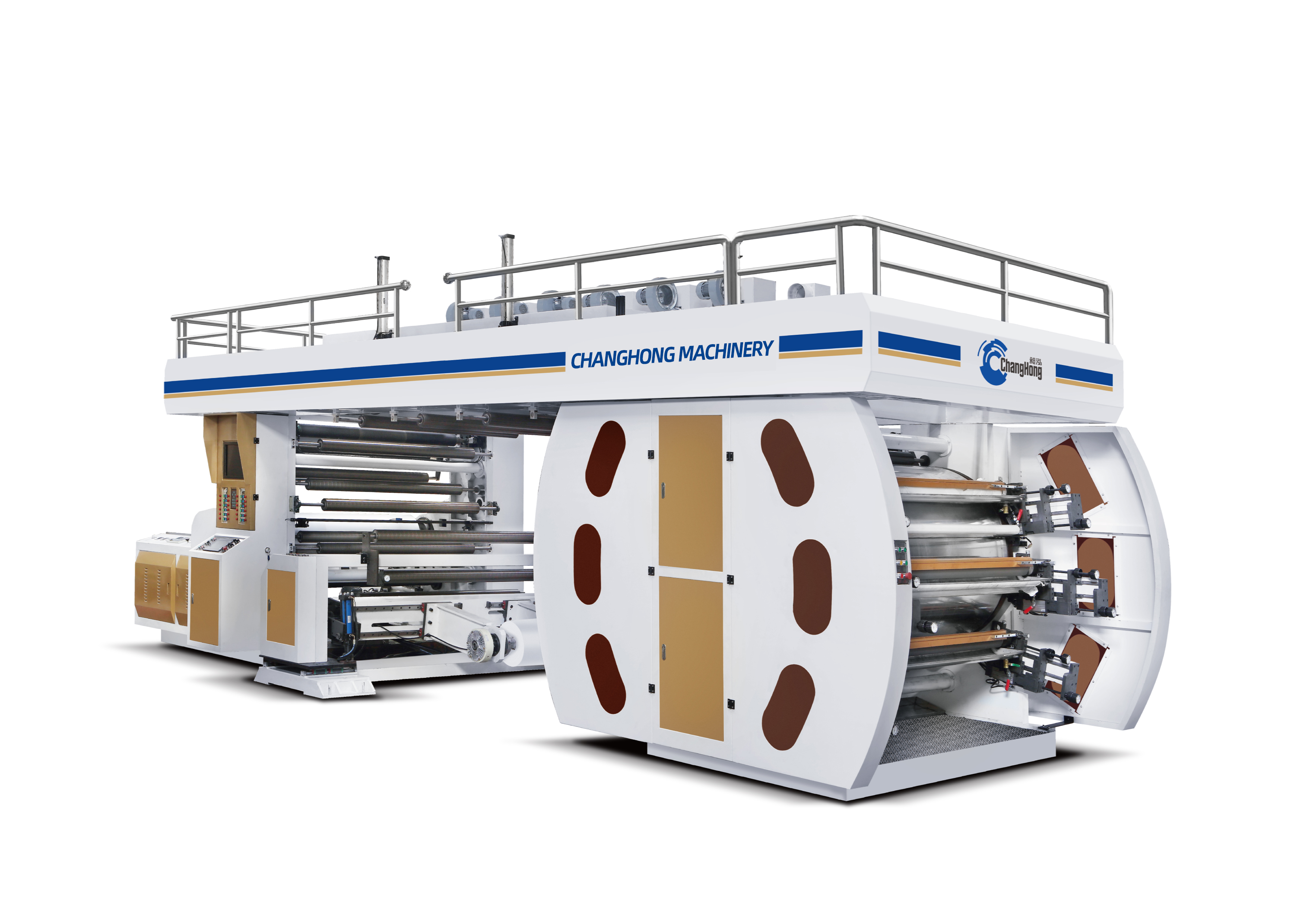

khatiso ea mahlakoreng a mabeli mochine oa khatiso oa CI flexo bakeng sa pampiri / sekotlolo sa pampiri / lebokose la pampiri

khatiso ea mahlakoreng a mabeli mochine oa khatiso oa CI flexo bakeng sa pampiri / sekotlolo sa pampiri / lebokose la pampiri

lintlha tsa tekheniki

| Mohlala | CHCI6-600E-Z | CHCI6-800E-Z | CHCI6-1000E-Z | CHCI6-1200E-Z |

| Max. Bophara ba Web | 700 limilimithara | 900 limilimithara | 1100mm | 1300 limilimithara |

| Max. Bophara ba Khatiso | 600 limilimithara | 800 limilimithara | 1000mm | 1200 limilimithara |

| Max. Lebelo la Mochini | 350m/min | |||

| Max. Lebelo la ho Hatisa | 300m/min | |||

| Max. Fokotsa/Khutlisa Dia. | Φ1200mm/Φ1500mm | |||

| Mofuta oa Drive | Moropa o bohareng o nang le Gear drive | |||

| Letlapa la Photopolymer | Ho hlalosoa | |||

| Enke | Enke ea motheo ea metsi kapa enke ea solvent | |||

| Bolelele ba Khatiso (pheta) | 350mm-900mm | |||

| Mefuta e fapaneng ea li-substrates | Pampiri, Komiki ea pampiri, E sa Lohiloeng | |||

| Phepelo ea Motlakase | Motlakase oa 380V. 50 HZ.3PH kapa e tla hlalosoa | |||

Selelekela sa Video

Likarolo tsa Mochini

1.Shaftless Unwinding Design: Mochini ona oa khatiso oa CI flexo o nka mokhoa oa ho phutholla shaftless, o nolofalletsang ho kenya ka ho feletseng le ho emisa thepa ea marang-rang. Ts'ebetso ea phetoho ea thepa e potlakile, hape e fokotsa tahlehelo ea li-clamping tsa substrate, ka hona e ntlafatsa ts'ebetso e sa sebetseng le sekhahla sa ts'ebeliso ea thepa ea khatiso ea liphutheloana.

2.Sistimi e ikemetseng ea ho khutlisa likhohlano: E na le sesebelisoa se ikemetseng sa ho khutlisa likhohlano, se ka fetola tsitsipano habonolo ho latela litšoaneleho tsa li-substrates tse fapaneng tse kang likotlolo tsa pampiri le tsa pampiri. Sena se tiisa matsoelintsoeke a bataletseng ntle le wrinkles, ho etsa hore mochini oa khatiso oa ci flexo o feto-fetohe haholoanyane ha o ntse o etsa matsoelintsoeke mme o ikamahanye le litlhoko tsa lihlahisoa tse phethiloeng tse entsoeng ka pampiri.

3.Half-web Turn Bar bakeng sa Khatiso e Mahlakoreng a Habeli: E na le lisebelisoa tsa mantlha tse nang le foreimi e phetholang halofo ea bophara, e ka hlokomelang ka ho toba khatiso ea mahlakore a mabeli ka nako e le 'ngoe ntle le tlhokahalo ea ho seta mochine oa bobeli. Sena se khutsufatsa haholo potoloho ea tlhahiso ha se ntse se netefatsa ho nepahala ha ngoliso ea mekhoa ea mahlakoreng a mabeli, ho nolofalletsa mochine oa khatiso oa CI flexographic hore o finyelle tlhahiso e ntle ea mahlakore a mabeli.

4.Bokhoni ba ho hatisa ka lebelo le phahameng la 350m / min: E na le bokhoni ba ho hatisa ka lebelo le phahameng la limithara tse 350 ka motsotso. Sebopeho sa eona se matla sa mechine le tsamaiso ea ho khanna e tiisa ts'ebetso e tsitsitseng ka lebelo lena le phahameng, e leng se etsang hore e tšoanelehe bakeng sa tlhahiso ea liphutheloana tse entsoeng ka pampiri e phahameng le ho arabela ka potlako litlhoko tsa taelo.

5.Tlhahiso e Phahameng ea ho Ngolisa e Ngolisoe: Ho itšetlehile ka sebopeho sa CI (Central Impression Cylinder), e ka laola ka nepo ho kheloha ha ho ngolisoa ha mokhoa. Esita le ka lebelo le phahameng, e ntse e ka fana ka lihlahisoa tse hatisitsoeng tse nang le mekhoa e hlakileng le ho se khetholle mebala, ho finyella litlhoko tsa boleng bo phahameng ba liphutheloana tse entsoeng ka pampiri.

Lintlha Dispaly

Mehlala ea Khatiso

Mehlala ea khatiso ea mochine ona oa khatiso oa 6-color CI flexographic o lumellana le li-packaging substrates tse entsoeng ka pampiri tsa mefuta e sa tšoaneng, ho akarelletsa le pampiri, linoelo tsa pampiri, likotlolo tsa pampiri le mabokose a pampiri.

Ntle le ho nkela likarolo tsa mantlha khafetsa, o ka fetola kapele lipakeng tsa tlhahiso ea sampole bakeng sa li-substrates tse fapaneng ka ho fetola liparamente tsa khatiso. Sena ha se khutsufatse feela potoloho ea tlhahiso ea sampole empa hape se fokotsa litšenyehelo tsa phetoho ea lisebelisoa, ka hona, ho fihlela litlhoko tsa boleng bo holimo bakeng sa lisampole tse fapaneng tsa ho paka.

Packaging And Delivery

Re fana ka tšehetso e felletseng bakeng sa mochini oa hau oa khatiso oa CI flexo. Mohato o mong le o mong ho tloha fekthering ho ea workshop ea hau e ka lateloa, 'me u tla khona ho latela boemo ba thepa ka nako efe kapa efe. Kamora hore lisebelisoa li fihle, sehlopha sa rona sa litsebi se tla fana ka tataiso ea ho laolla setšeng, tlhahlobo ea setšeng, le lits'ebeletso tsa ts'ebetso ea lisebelisoa ho netefatsa ts'ebetso e bonolo ho tloha ho rasiti ho isa ho thomo, ho u fa khotso e felletseng ea kelello.

LBH

Q1: Phapano ke efe lipakeng tsa ho khutlisa likhohlano tse ikemetseng le ho khutlisa khafetsa?

A1: Ho khutlela morao khafetsa: tsitsipano e tsitsitseng, ho se feto-fetohe ha maemo, ho lokoloha habonolo / ho otlolla.

Ho khutlisa likhohlano tse ikemetseng: tsitsipano e feto-fetohang, li-substrates tse ngata, ho khutlisa sephara, liphetoho tse potlakileng.

Q2: Ke li-substrates life tse sebetsang le khatiso ea pampiri ea flexo?

A2: E ts'ehetsa pampiri ea 20-400 gsm, likotlolo tsa pampiri, le mabokose. Li-parameter li ka fetoha ntle le ho fetola likarolo tsa mantlha.

Q3: Na ho fetola li-substrates (mohlala, pampiri ho ea likotlolong tsa pampiri) ho thata?

A3: Che. Shaftless feeding + rewinding system e lumella phetoho e le 'ngoe ea parameter; koetliso ea motheo e lekane bakeng sa ts'ebetso.

Q4: Na mochine oa khatiso oa flexo o ka etsoa?

A4: Ho joalo. Litlhophiso tsa bohlokoa li ka etsoa ho latela litlhoko tsa hau tsa tlhahiso. Ikopanye le rona ka litlhoko tse khethehileng.

Q5: Na u fana ka koetliso ea ts'ebetso?

A5: Ho joalo. Baenjiniere ba fana ka koetliso ea ts'ebetso le tlhokomelo sebakeng sa marang-rang nakong ea ho kenya ho thusa sehlopha sa hau ho tseba lisebelisoa kapele.